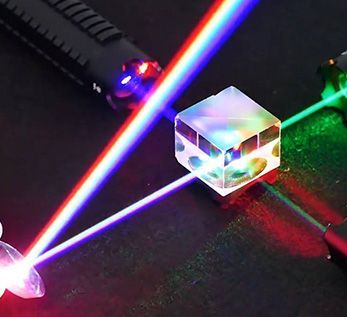

All of the gas worked as material of laser called laser gas. It is the sort on the world most, developing the fastest, application the widest laser. One of the most important characteristics of lasers gas is the laser work material is mixture gas or a single pure gas.

The working substance used by gas laser can be atomic gas, molecular gas, ionized ion gas and metal vapor, etc., so it can be called atomic laser gas (such as helium-neon laser) and molecular laser gas (such as carbon dioxide). Laser), ion laser gas (such as argon laser), metal vapor laser (such as copper vapor laser). Generally speaking, because of the inherent characteristics of the laser gas, there are some characteristics resulting from it; the advantages are: the gas molecules are evenly distributed and the energy level is relatively simple, so the light quality of the laser gas is uniform and coherent.

Better; In addition, the gas molecules convection and circulate faster, and are easy to cool down. One of the most important characteristics of laser gas is that the laser working material is a mixed gas or a single pure gas. The purity of the component gas in the laser mixed gas directly affects the performance of the laser. In particular, the presence of impurities such as oxygen, water, and hydrocarbons in the gas will cause the loss of the laser output power on the mirror (surface) and the electrode, and also cause the laser Unstable launch. One of the important characteristics of gas laser gas, the working substance of the laser is a mixed gas or a single pure gas. Therefore, there are special requirements for the purity of the laser mixed gas components. The cylinders for packaging the mixed gas must also be dried before filling to prevent contamination mixed gas. If the helium (He) neon (Ne) laser is used as the first generation gas laser, and the carbon dioxide laser is the second generation gas laser, the krypton fluoride (KrF) laser, which will be widely used in the semiconductor manufacturing field, can be called the third generation laser . Laser gas mixture is used in industrial production, scientific research and national defense construction, medical surgery and other fields.

Evenly distributed gas molecules: In the laser mixed gas, the gas molecules can be evenly distributed, which makes the laser output beam quality more uniform and coherent.

Relatively simple energy level structure: The energy level structure of gas molecules is relatively simple, which helps to achieve efficient and stable laser emission.

Good cooling performance: Gas molecules have a faster convection cycle speed and are easy to dissipate heat, thus ensuring the stable operation of the laser.

High purity requirements: The purity of the component gases in the laser mixed gas directly affects the performance of the laser. The presence of impurities such as oxygen, water and hydrocarbons will cause the laser output power to decrease, and will also cause the problem of unstable laser emission. Therefore, there are special requirements for the purity of the components of the laser mixed gas, and the gas cylinders that package the mixed gas must also be dried before filling to prevent contamination.

Industrial production: For example, in the fields of precision machining, material cutting and welding, laser technology can provide high-precision and high-speed processing capabilities.

Scientific research: In physics, chemistry and biology research, laser mixed gases are used in various experiments to help scientists explore the mysteries of the microscopic world.

National defense construction: Laser technology is also widely used in the military field, including precision-guided weapon systems, radar systems, etc.

Widely used in industrial agricultural production, scientific research, national defense, medical surgery and laser processing.

Widely used in industrial agricultural production, scientific research, national defense, medical surgery and laser processing.

Widely used in industrial agricultural production, scientific research, national defense, medical surgery and laser processing.

Widely used in industrial agricultural production, scientific research, national defense, medical surgery and laser processing.

| Category | Component | Balance Gas |

| He-Ne Laser Mixture Gas | 2~8.3 % Ne | He |

| CO2 Laser Mixture Gas | 0.4%H2, 13.5%N2, 4.5%CO2, 2%CO | He |

| 0.4%H2, 13%N2, 7%CO2, 4%CO | ||

| 0.4%H2, 8%N2, 8%CO2, 2%CO | ||

| 0.4%H2, 6%N2, 8%CO2, 4%CO | ||

| 0.4%H2, 16%N2, 16%CO2 | ||

| 0.4%H2, 8-12%N2, 6-8%CO2 | ||

| Kr-F2 Laser Mixture Gas | 5%Kr, 10%F2 | He |

| 5%Kr, 1~0.2%F2 | ||

| Sealed Beam Laser Gas | 18.5%N2, 3%Xe, 2.5%CO | He |

| Excimer Laser Gas | 0.2-0.3%F2, 9-11%Ar, 20-30%Ne | He |

| 0.1-0.25%F2, 3-5%Ar | Ne | |

| 0.1-0.2%F2, 1-3%Ar, 2-3%He | ||

| 5-8%Ar, 2-4%He | ||

| 0.1-0.3%F2, 5-8%Ar | ||

| 0.1-0.3%F2, 5-8%Ar, 2-4%He | ||

| 0.1-0.4%F2, 3-10%Ar, 3-25%He | ||

| 0.2-0.4%F2, 6-10%Ar, 25-32%He | ||

| 0.1-0.3%F2, 2-8%Ar, 5-12%He | ||

| 0.1-0.3%F2, 2-10%Ar, 3-8%He | ||

| Rofen Laser Gas | 4%CO2, 6%CO, 3%O2, 3%Xe, 19%N2 | He |

| Cutting Laser Gas | 10-34%CO2 | He |

| 4.5-16%CO2, 5.5-55%N2 | ||

| 8-32%N2, 8-16%CO2, CO | ||

| 16.5%N2, 8%CO2, CO |

*Other Grades and Purity Available on Asking

Package Information

10L,16L, 20L, 47L or 50L cylinder.

*Other Packages Available on Asking

Loading Reference

Advantanges

More than fifteen years on the market.

ISO certificate manufacturer & Stable raw material source.

On-line analysis system for gas quality control in every step, highly close to 100% pass rate.

Experienced DG International Shipping Team by sea & air.